18122929151

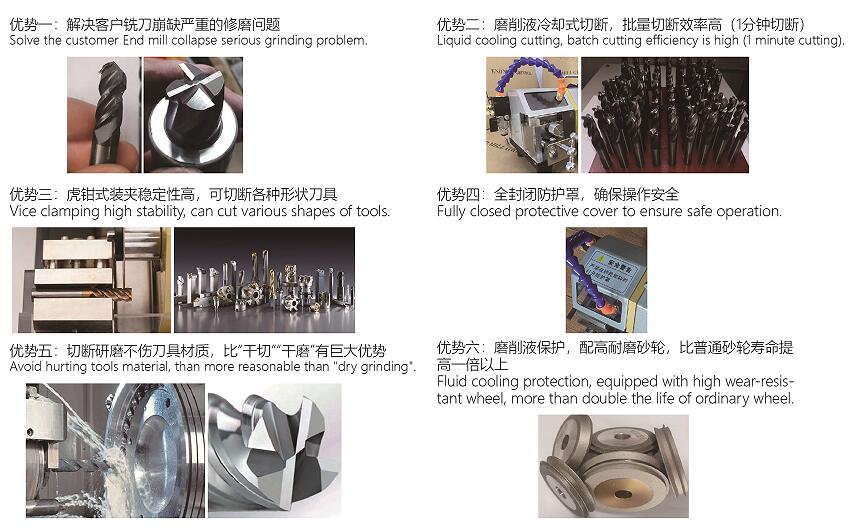

1.一机两用,既可以研磨端铣刀,又可以实现刀具高速切断功能;

One machine dual use, grind the end End mill, cutting tools high-speed.

2.铣刀研磨可实现2/3/4刃钨钢及高速钢端铣刀研磨;

Applicable for 2/3/4 flutes tungsten carbide and high speed steel end milling.

3.研磨铣刀部位为刀刃角、前斜角和后斜角;

Grinding End mill parts are blade Angle, front bevel Angle and back bevel Angle.

4.铣刀第一后角宽窄可调,以适用不同硬度材料切削;

The width of the first back Angle of the End mill can be adjusted to apply to different hardness materials cutting.

5.操作方便,任何人观看视频后都可以实现一分钟磨好一把铣刀;

Easy to operate, anyone watching the video can achieve a minute to grind a End mill.

6.磨削液冷却式研磨研磨精度和光洁度高,刀具材质不受伤害,比采用”干磨方式研磨的铣刀耐用性大幅提高;

Liquid cooling grinding, grinding precision and finish is high, the tool material is not hurt, End mill durability greatly improved than "dry grinding"

7.切断功能部分采取虎钳装夹,稳定可靠,各类刀具轻松切断(不局限圆棒型);

Adopts vice clamping, stable and reliable, easy to cut off all kinds of tools (not limited to round rod type).

8.磨削液冷却式切断,切断瞬间温升大幅降低,切断效率及砂轮寿命大幅提高;

Liquid cooling cutting, cutting instant temperature greatly reduced, cutting eficiency and grinding wheel life greatly improved.

9.切断功能外加防护罩,切实避免切断过程对人身造成伤害。

Cut off function plus protective cover, avoid personal injury.

电 话:0769-81583875

手 机:18122929151

邮 箱:545713512@qq.com

地 址:广东省东莞市长安乌沙兴二路1号德兴刀具数控产业园502

扫一扫关注我们